PROTECH

Engine Coating Treatment

Extreme Pressure Test(Timken Test) Video

Please make sure to check the sound of the video.

- This is a test to check the friction that occurs when a Timken bearing ball is subjected to strong pressure against a rotating shaft.

- In the first test using 100% synthetic oil, a torque wrench is used to apply 10 foot-pounds of force.

- Severe friction between the two metal surfaces generates noise and high heat.

- In some cases, excessive frictional heat may cause the oil to burn or the bearing to stick to the shaft.

- After adding the PROTECH product, the same torque wrench is used to apply 10 foot-pounds of force, gradually increasing it up to 40 foot-pounds.

- PROTECH forms a coating on the metal surfaces, eliminating friction and preventing heat generation.

- Even after removing the container and conducting the test, friction does not occur due to the already-formed coating layer.

ENGINE Coating is BASIC!

Oil Life, 3x Extension!

The ultra-fine ionic film that coats the engine's metal surfaces significantly minimizes friction, inhibits oil oxidation at elevated temperatures, and extends the lifespan of the oil.

Patent No. 10-2090301

Even coats the sound!

Old Engine, Like New!

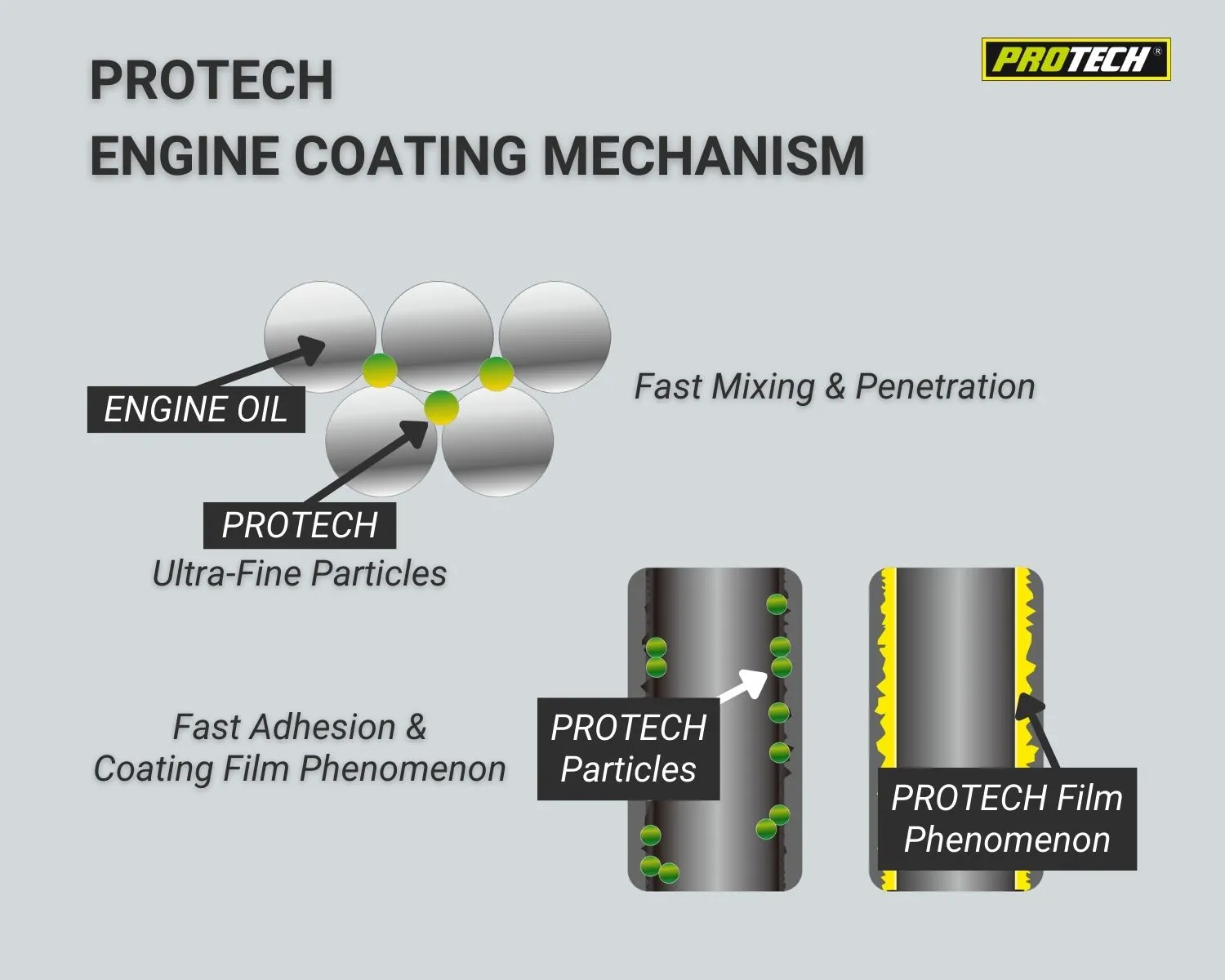

As shown, the fine particles of the PROTECH component quickly penetrate the engine oil, adhere to the metal surfaces, and form a protective nanocoating inside the engine. Consequently, even older engines run smoothly and quietly, just like new ones.

Features

Engine oil alone has limitations in preventing wear caused by high-temperature and strong, high-pressure friction. The PROTECH prevents engine wear 15 to 30 times by adding a polar pressure coating agent.

Proposal for Bus Company

Engine Life Extension

The lubricity against immediate impact (extreme pressure) inside the engine increases 5~10 times to protect the engine.

Friction and Wear Reduction

It forms a strong coating film on the part where friction occurs inside the engine to prevent further wear.

Engine Power Increase

It increases the power of the engine by minimizing the overload, noise, smoke, and vibration caused by friction.

Fuel Efficiency Increase

It is economical as the engine power strengthens, the fuel efficiency increases by more than 5%, and the oil change period doubles or more.

Lower Temperature

It maintains low temperatures even in harsh engine environments due to reduced friction inside the engine.

Vibration & Noise Reduction

High lubrication of engine oil reduces engine vibration and noise.

Always, Like New!

New cars can be kept in new engine conditions until scrapped and maintain used vehicles in the best condition by improving the engine.

Patented Product

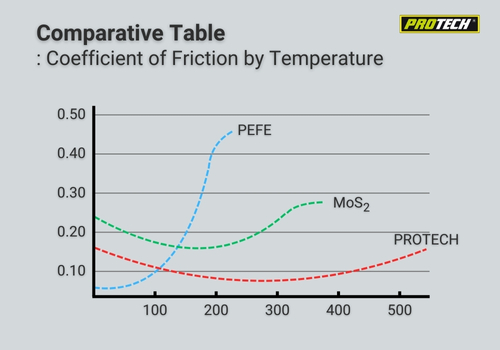

Some products use P.T.F.E. solid substances to cause side effects. However, the PROTECH is manufactured based on synthetic hydrocarbons and pure minerals. Hence, there are no side effects ever, incomparable to existing coatings!

PROBLEM

From the onset to the conclusion of driving, the engine endures a continual cycle of friction and wear, which ultimately gives rise to minute scratches on the metal surface.

DRY START-UP

- The most significant wear and tear on an engine occurs during its initial start-up each morning.

- When a vehicle has been stationary for an extended period, the majority of the engine oil settles at the bottom, leaving the cylinder walls inadequately lubricated.

- This lack of lubrication can lead to fine scratches caused by the friction between metal surfaces as the engine engages.

- Consequently, this results in increased noise and smoke, a decline in power output, and diminished fuel efficiency.

HIGH FRICTION & TEMP

- The elevated temperatures and frictional heat generated by the piston, the inner walls of the cylinder, and the crankshaft diminish the lubricating properties and overall effectiveness of engine oil.

- This not only places significant stress on the engine but also gradually undermines both fuel efficiency and acceleration performance.

SEVERE DRIVING CONDITIONS

- Driving conditions characterized by frequent starts and stops.

- Vehicles that do not have adequate time to allow the engine to warm up due to short trips.

- Vehicles carrying substantial loads.

- Vehicles frequently operated in high-temperature environments exceeding 30 degrees Celsius.

- Vehicles traversing sandy or dusty terrains.

- Vehicles that regularly navigate mountainous or steep inclines.

Product Information

PROTECH Engine Coating Treatment

Volume

MOTORCYCLE : 75ml / 100ml

4-WHEEL : 500ml

Addition Ratio

8-13% of engine oil capacity

Applicable Engine

Gasoline / Diesel / LPG

Performance Test Results

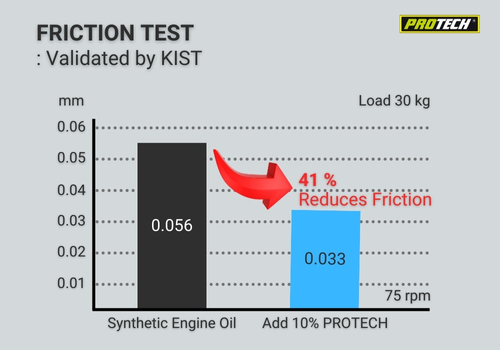

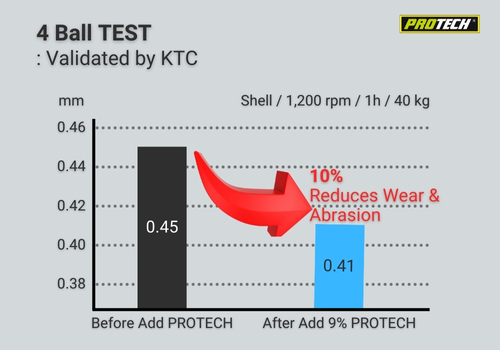

This is the result of a mechanical wear resistance evaluation conducted by a prestigious testing institution in Korea.

FRICTION TEST / KIST

- Method Used: Ring on Block Tester

- Rotational Speed: 75 rpm

- Load Applied: 30 kg

- Measurement: Coefficient of friction

- Result : 41% reduction in friction

4 BALL TEST / KTC

- Method Used: 4-Ball Tester

- Rotational Speed: 1,200 rpm

- Load Applied: 40 kg

- Test Focus : Wear resistance

- Result : 10% reduction in friction

- Certification Obtained : Q mark from the relevant institution

COMPARATIVE TABLE

- Products Tested : PROETCH & Two other products with different main components

- Product with the least temperature change due to friction : PROETCH

- Product with the least change in coefficient of friction : PROETCH

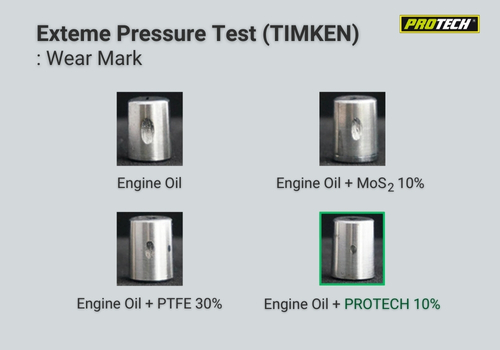

EXTREME PRESSURE TEST

This is a comparative photograph of wear marks caused by friction under extreme pressure.

Question

& Answer

A few things clients normally ask us about the PROTECH Engine Coating Treatment.

- The PROTECH, engine coating treatment, is more effective when used from a new car.

- The PROTECH can maintain the engine condition of a new car for a longer period of time.

- The PROTECH can be used regardless of the time of changing oil, but it is more effective if you use it when changing.

- In the case of vehicles traveling within 1,000 km after changing the engine oil, only add it.

- However, if it is driven longer than that, use the PROTECH when changing the oil.

- The PROTECH does not contain any solid substances that may cause adverse effects on the engine.

- Particularly P.T.F.E (Teflon) - based material blocks the filter and prevents the smooth flow of oil.

- The PROTECH made ionic bonding between metals possible using a new material blending technique.

- The PROTECH, which became a part of the metal, does not change the thickness of the metal and does not damage the engine.

- PROTECH is already a well-established product among heavy equipment and huge truck users in Korea.

- It is not only because of the quality of the product but also because of the reasonable price.

- We maintain reasonable prices by reducing unnecessary advertising costs.

- Yes, you can.

- PROTECH recommended addition ratio is 6-13%.

- 75 ml is the minimum recommended rate of 6% applied to the 1.2L engine. (1,200ml * 0.06 = 72ml)

- This means that a minimum of 75 ml PROTECH is sufficient for the 1.2 liter engine.

- However, applying the maximum recommended ratio to the 0.8 liter engine results in 104ml.

- Therefore, you can use 100ml products for 0.8L engines as well, rather you can get better results.

- Of course, there is no problem with using it. Rather, it is positive in terms of cost reduction.

- Put 8 ~ 13% of Engine Oil Capacity.

How to Use

Unplug drain bolt and drain old oil.

Start the work after idling for 2-3 minutes for smooth oil discharge.

Find and remove oil filter.

After removing the oil filter, remove the remaining oil by blowing air.

Plug drain bolt and filter on.

Refit the oil filter and securely tighten the drain bolts.

Put PROTECH into the engine oil filler.

Add 5 to 13% of the engine oil capacity in the manual.

Fill up with new engine oil.

Fill the engine oil while checking the dipstick.

Start engine.

Close the engine oil filler and start the engine. Feel your engine that's completely changed.